Tsubame Bussan Co., Ltd. Factory Tour Audio Guide (English)

Welcome to the Tsubame Bussan factory tour.

This guide is self-play style, with numbers assigned to each work area and machine on site.

During your tour, please press the playback button corresponding to the assigned number.

The explanation of that process will play, linking the narration with the work you are seeing.

Listen carefully while watching the machines and artisans in front of you.

≪Important requests to all visitors≫

・The factory is loud with machine noise, so please raise the volume of the audio guide. (If you use earphones, please use only one ear for safety.)

・The factory is dangerous, so always follow the staff's instructions.

・Photography is generally prohibited. Please enjoy only in designated photography areas.

・Do not touch machines or products without permission.

・Please do not enter restricted or no-entry areas.

・Watch your step as floors may be slippery or uneven.

・If rules cannot be followed, staff may ask you to stop the tour. Please understand.

≪About this project≫:Copyright and Intellectual Property Notice

The “(tentative) Universal Factory (Audio Guide)” is an original factory experience program independently planned, developed, and produced by Tsubame Bussan Co., Ltd., with the aim of enabling each visitor’s experience to transform the way they view and choose products, ultimately contributing to the future of the region and its industries.

All components of this program—including its structure, scenario, audio data, texts, production methods, and overall experiential design—are protected under copyright law and other relevant intellectual property rights. Any unauthorized recording, filming, reproduction, adaptation, distribution, public transmission, translation, or the creation of derivative or imitative programs for commercial use is strictly prohibited.

In the event of any infringement, legal action may be taken pursuant to copyright law and other applicable regulations. Please note that this program is currently being specially released as a trial, while intellectual property rights applications are in progress.

We kindly ask for your understanding and cooperation so that everyone may enjoy the unique experiential value that only Tsubame Bussan can provide.

≪Audio Guide Playback Time≫

Process only: 12 min 59 sec

Process + episodes: 20 min 45 sec

▶ Marks indicate side stories by our company executive. Please enjoy them between main process narrations.

© Tsubame Bussan Co., Ltd. 2025 All rights reserved.

This audio guide has been independently produced to convey the craftsmanship more deeply.

To protect the value of this experience, unauthorized reproduction or reuse is strictly prohibited.

Welcome to the Molding Factory 【Area A】

▶S1.The Origin of the Spoon

The first site you will see is the molding process where the shape of cutlery is formed from stainless steel metal sheets, the raw material.

This factory produces about 150,000 spoons and forks every month. There are two production lines.

One is a manual line handed down for over 100 years by skilled artisans. The other is an automated line using robot arms.

The basic flow is the same, but there are differences in the types of materials that can be processed and the freedom of design.

Please observe how functional beauty is given to the hard and cold metal sheets.

And pay attention to the artisans efficiently performing delicate tasks.

P1. "Material Cutting" (Mass Cutting)

Number P1, "Material Cutting" process.

Tsubame Bussan cutlery is born from this high-quality stainless steel. They cut only the required amount from stainless steel coils weighing over 10 tons and process it into rectangular sheets

about one meter on each side.

Next, they further cut these into smaller rectangular sheets suited to the size of spoons and forks. This step is called "mass cutting." Dimensions are strictly calculated to optimize yield and

minimize waste.

The cutting machine makes a sharp “kachan” sound, proof that the sharp blade is cutting precisely.

Skilled artisans can detect even slight errors from the sound and feel of the blade. If cutting is not done correctly, uneven edges remain and cause problems in later processes.

From this stage, the story of each piece of cutlery begins.

P2."Jinuki" (Blanking)

Number P2, “Jinuki” (Blanking) process.

In this step, spoon and fork shapes are efficiently punched out from metal sheets. By arranging the shapes alternately, more pieces can be cut out with less waste.

Please also pay attention to the scrap metal from the blanking process—this shows the ingenuity and craftsmanship in using materials to their fullest extent.

The metal sheet is set into the mold and pressed, creating a sharp “batun” sound as the silhouette of the spoon emerges. It is still flat at this stage, but the handle outline is created here for the first time.

If the blanking is not done correctly, uneven or twisted edges remain on the cut surfaces, preventing the production of beautiful cutlery.

Artisans responsible for forming say, “The defect rate is all determined by the precision of the blanking. It is a crucial, irreversible process.”

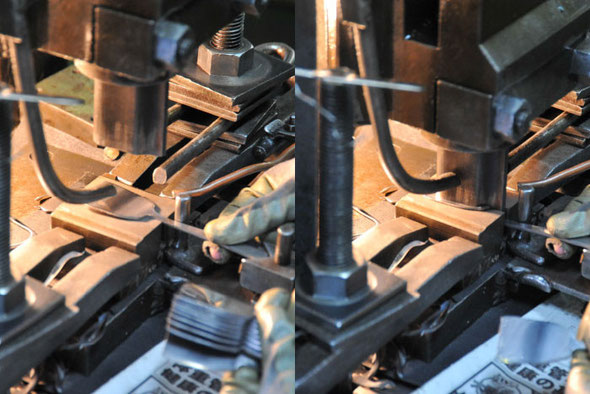

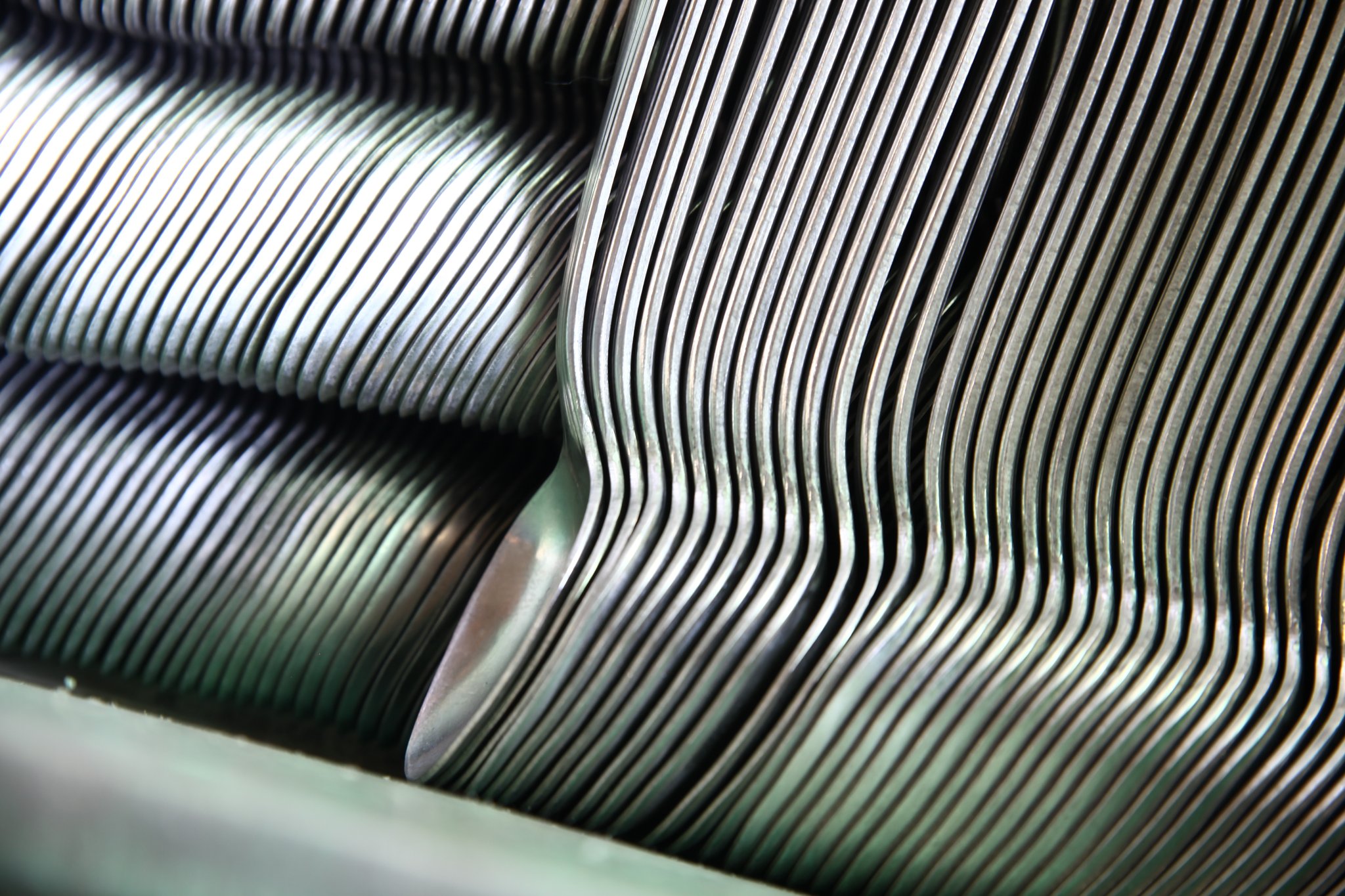

P3."Roll"

Number P3, "Roll" process.

In this step, metal is stretched with rollers, gradually thinning and widening the head—the scooping part of the spoon. This process determines how easily the spoon can scoop and how comfortable

it feels in the mouth.

The sound heard is a rhythmic "dan, dan, dan" accompanied by a distinctive scraping noise.

Craftsmen judge changes from the sound and the slight resistance felt in their hands, adjusting the number of roller passes and rolling stages accordingly. Although the stainless steel may appear the same, its hardness and stretchability vary depending on production batches and the day’s temperature.

In the deep snowy winter, you may see metal warmed by kerosene stoves before processing. Please watch the artisans working faster than robot arms, at speeds almost invisible to the eye.

You might notice they flip the metal back and forth every few passes. Through sound and touch alone, they discern micro-level thickness changes and finish with precision. There’s no need for frequent checks—the perfectly finished cutlery stacks up automatically, a scene made possible by skilled craftsmanship.

▶S2.The Secret of Thinness

Actually, how thin the head part of the cutlery should be stretched for ease of use is said to be the optimal solution derived from 300 years of accumulated experience since the birth of cutlery.

At Tsubame Bussan, materials up to 5 millimeters thick are used, but the tip of the spoon should be thinned to 1.5mm for a main meal, 1.2mm for a dessert or coffee spoon, and 1.8mm for the tip of a fork.

This thinness specification is an "unspoken rule" in the industry. It is not written on the drawings but has naturally been followed through years of experience and craftsmen’s intuition.

The key to ease of use is that the thickness gradually becomes thinner toward the tip. The change in head thickness is very important. However, the two metal rollers that rotate during the rolling process rotate in parallel. If processed normally, the thickness should be uniform. So how do they create this change in thickness?

That is a company secret. It is an invisible world of ingenuity known only to the hands and experience of the craftsmen.

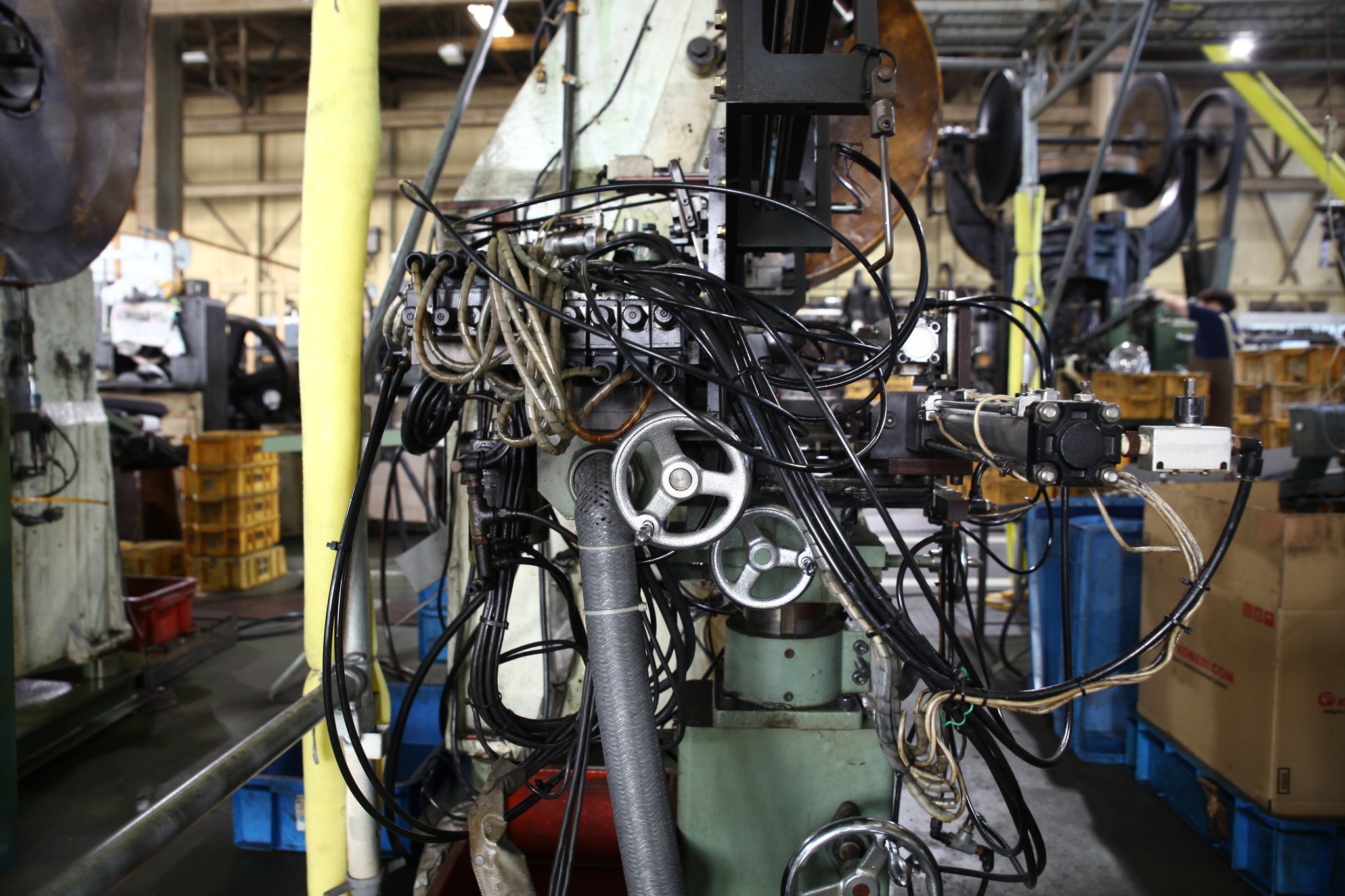

P4."Hankiri"(Half Cutting)

Number P4, “Hankiri” (Half Cutting) process.

In this step, the final silhouette of the spoon is punched out using a press. At this moment, you can clearly recognize the shape for the first time: “Oh, this is a spoon” or “This will become a fork.” This process is like a “check” of all previous processing.

If there are uneven cutting surfaces or metal twisting and thickness defects remaining, correct processing cannot be done. In the worst case, it results in a completely defective product that cannot be sold.

If lucky, you may see skilled artisans carefully comparing the shape with the process sample from the side. Here, sharp eyes and seasoned senses come alive.

P5."Blade Cutting"

Number P5, "Blade Cutting" process.

In this step, the blades of the fork are made by pressing. It is often thought that the fork head is shaped in a single press. However, in reality, after creating the silhouette in the half-cutting step, the blade is processed in two stages.

To achieve the slenderness that allows easy piercing, it is necessary to take care not to twist or chip the blades, even if it requires extra effort. First, the sides of the blades are pressed in the first pressing. Then, the center is punched out in the second pressing, completing the blade.

This simply doubles the number of steps. For example, when producing 10,000 forks, the pedal must be pressed 20,000 times just for blade cutting. Each fork carries this steady accumulation of effort.

▶S3.Why does a fork have four tines?

NHK's popular show "Chico-chan ni Shikarareru!" commissioned us to create a special fork to verify its ease of use and find out why.

The fork was born in ancient Egyptian civilization, originally with two tines used as a cooking tool to probe ingredients in pots and to stab food. It became used for dining around the 11th century, spreading from the Byzantine Empire throughout Europe. In the 18th century, the three-tine fork became mainstream for ease of use. Then, by order of King Ferdinand of Naples, Italy, the four-tine fork was developed to eat spaghetti more easily. At that time, spaghetti was common food eaten by hand. To eat it gracefully at court, the king ordered his aides to develop a "fork easy to spin spaghetti." Thus, the four-tine fork, born for spaghetti, became widely used from nobles to commoners for many foods.

At Tsubame Bussan, we have also independently developed a three-tine special pasta fork. Its tip flares out specially for even easier spaghetti twirling.

P6. "Handle Pressing"

Number P6, "Handle Pressing" process.

In handle pressing, the three-dimensional shaping of the handle—directly related to ease of holding and use—is performed. This process also includes adding raised and recessed designs as well as stamped markings such as material information.

Both the front and back are processed at once. It is supported by precise molds that skillfully distribute the metal and pressing force while embossing fine patterns. The edges and corners of the broken surfaces are rounded to fit comfortably in the hand and to prepare for the polishing process that follows.

Please pay attention to the rhythmical movements of hands and feet working separately yet harmoniously as the shaping proceeds smoothly.

▶S4.People who turn cutlery over are industry insiders!?

In local Tsubame restaurants, you may see people turning over spoons and forks to look underneath. Actually, the back sides of handles and heads are engraved with material information, country of production, and the manufacturer’s logo.

When people find cutlery that is easy to use, they often instinctively check the back side, almost as a habit. If the letters "TBCL" or a cherry blossom mark are engraved on your cutlery, it is a Tsubame Bussan product.

Please take a moment while waiting for your food to notice the engraving on the cutlery you hold. There, you will find the mark of Tsubame, the town of craftsmanship.

P7."Tsubo pressing" or "Blade pressing"

Number P7, "Tsubo pressing" or "Blade pressing" process.

This step shapes the head part of the spoon or fork—the part that goes into the mouth—from a flat surface to a three-dimensional form.

Because this process dramatically changes the flat metal plate, delicate control is required. The metal shrinks on the inside surface and stretches on the outside.

If it fails, wrinkles or waves may appear, or in the worst case, the metal may crack. This is the final forming step in shaping. It serves as a check to confirm whether all previous steps were connected accurately.

Although artisans make this look easy at first glance, it takes at least five years of experience to be able to process the highest-grade Laurel series products.

▶S5.Flexion that tests the craftsman

Have you noticed that we use two different types of machines, even for the same pressing process? For half-cutting and blade punching, we use a *power press machine*, while for handle pressing, hollow pressing, and blade pressing, we use a *flexion press machine*. Our press machines were manufactured in the 1960s and 70s. Since producing new ones is difficult, we continue to repair and maintain the existing machines to keep them running.

Normally, machines operate under the same preset conditions. Once the switch is pressed, essentially anyone can process with the same pressure and speed. However, the flexion press machine is unique—it doesn’t have fixed movements and is controlled entirely by the craftsman’s right foot. Press harder, and the load becomes heavier. The machine is controlled by the depth, strength, and timing of each step on the pedal. After adjusting with a few pieces of cutlery, the craftsman continues to perform the same motion flawlessly, over and over.

So, please pay attention not only to the craftsman’s hands but also to their feet.

▶S6.In fact, the process we introduced is only a small part.

In this audio guide, we are introducing 13 processes. This is the minimum number of steps required to manufacture cutlery. For our finest product, the *Laurel* series, the number rises to 36 processes—more than twice the effort and time.

For example, the *bending* process. It reduces the strain on the mold, prepares the surface for precise reproduction of patterns and three-dimensional shapes, and also creates a natural fit when held in the hand. As the number of processes increases, the metal undergoes *work hardening*, making further processing more difficult. To counter this, there is also the *annealing* process, where the metal is heated to a high temperature to forcibly alter its structure and restore softness.

**annealing* process, Photo for reference.*

Welcome to the Polishing Factory 【Area B】

▶S7.The appearance of cutlery before it shines

Welcome to the Polishing Factory【Area B】The appearance of cutlery before it shines

As you move from the Forming Factory 【Area A】to the Polishing Factory 【Area B】, how does it feel?

The sounds you hear, the smell of oil, and even the sight of the craftsmen—it’s as if you’ve stepped into a completely different world.

The Tsubame-Sanjo area is well known for its division of labor, where multiple companies typically work together to complete a single product. Even one spoon may involve a company specializing in forming, another in polishing, and others in washing, inspection, and packaging. As Japan’s first specialized cutlery manufacturer, Tsubame Bussan has the unique strength of being able to handle integrated production. Being able to observe the entire process, from raw materials to shipping, is rare even in this region.

Before watching the polishing process, try touching the formed cutlery. The sides are uneven, the head feels rough, and traces of scratches from processing remain on the surface. In the polishing process you are about to see, this cutlery will be transformed into a smooth, comfortable piece to hold.

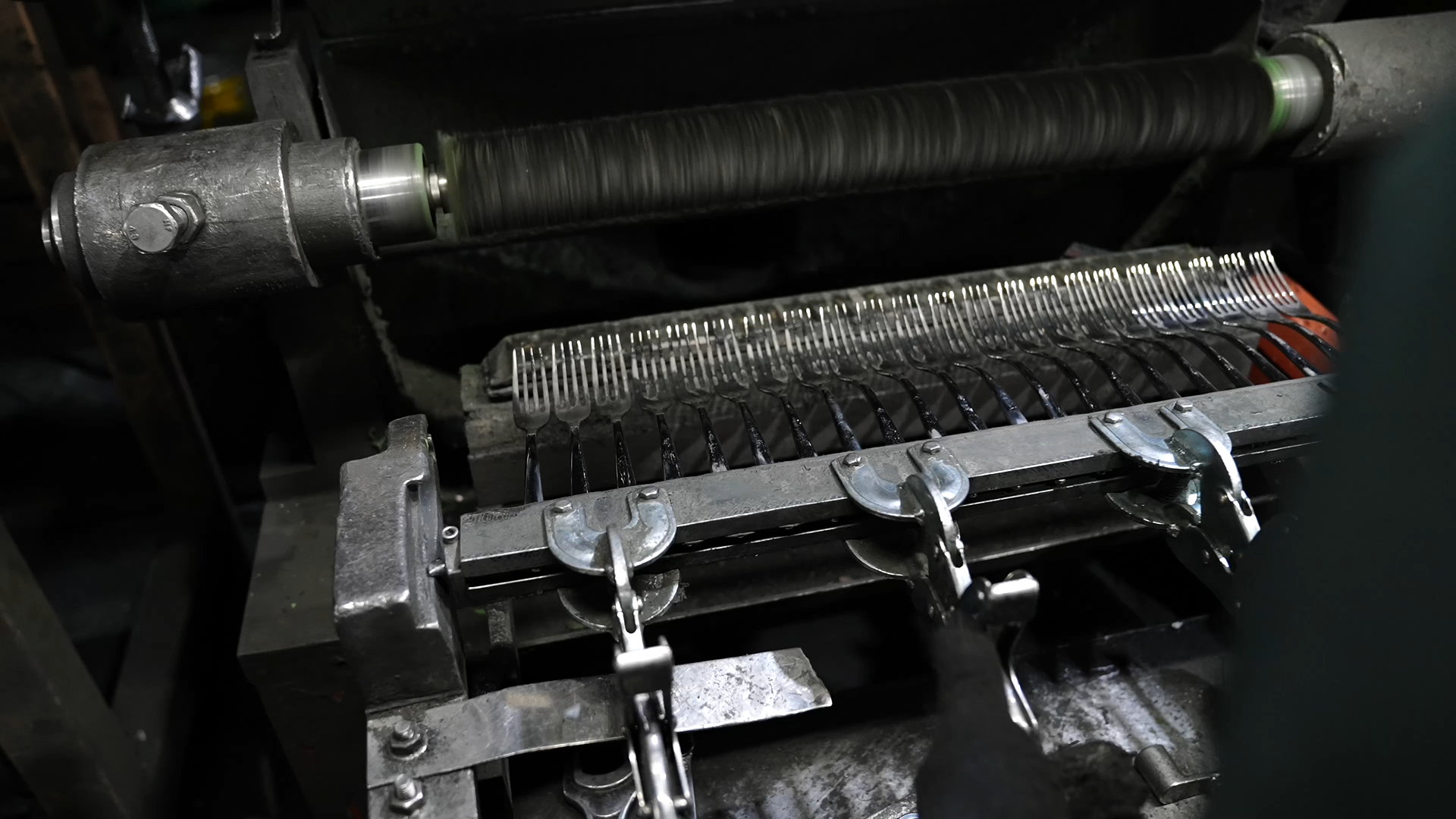

P8."Side Polishing" (Hand Polishing)

Process P8, ”Side Polishing”

Here, you can observe the process of polishing the sides of spoons and forks. By bundling several pieces together and pressing them against a high-speed rotating polishing machine, the sides of the metal gradually begin to shine. This work is a true hallmark of Tsubame’s craftsmanship.

Even today, it is not mechanized but carried out by hand, because it is a crucial process that directly affects the usability of cutlery. Using cloth buffs and polishing compounds, craftsmen adjust the combinations and polish each piece until it gleams like a mirror. The finer the product, the more polishing steps are required, resulting in even greater precision. In the end, the cutlery shines so brightly that it reflects the craftsman’s own face.

▶S8.Polishing Means Removing Material

It may seem obvious when put into words, but by removing just a tiny amount of material from the surface of cutlery, a beautiful shine, comfortable grip, and pleasant feel in the mouth are created. The craftsmen may appear to polish efficiently as if it were simple, but in reality, it is an extremely delicate and difficult task.

Careful control of force is essential to avoid erasing patterns or markings on the back. Polishing the same spot too much can create dents, so they constantly move the piece as a whole while finishing it.

Additionally, they use techniques to round edges so knives do not become too sharp. It would be impossible to rely on finger strength alone for an entire day, so they support themselves with their knees and use their whole body during the work.

Take another close look at the craftsmen’s hands. In each of their movements lies years of experience and skill.

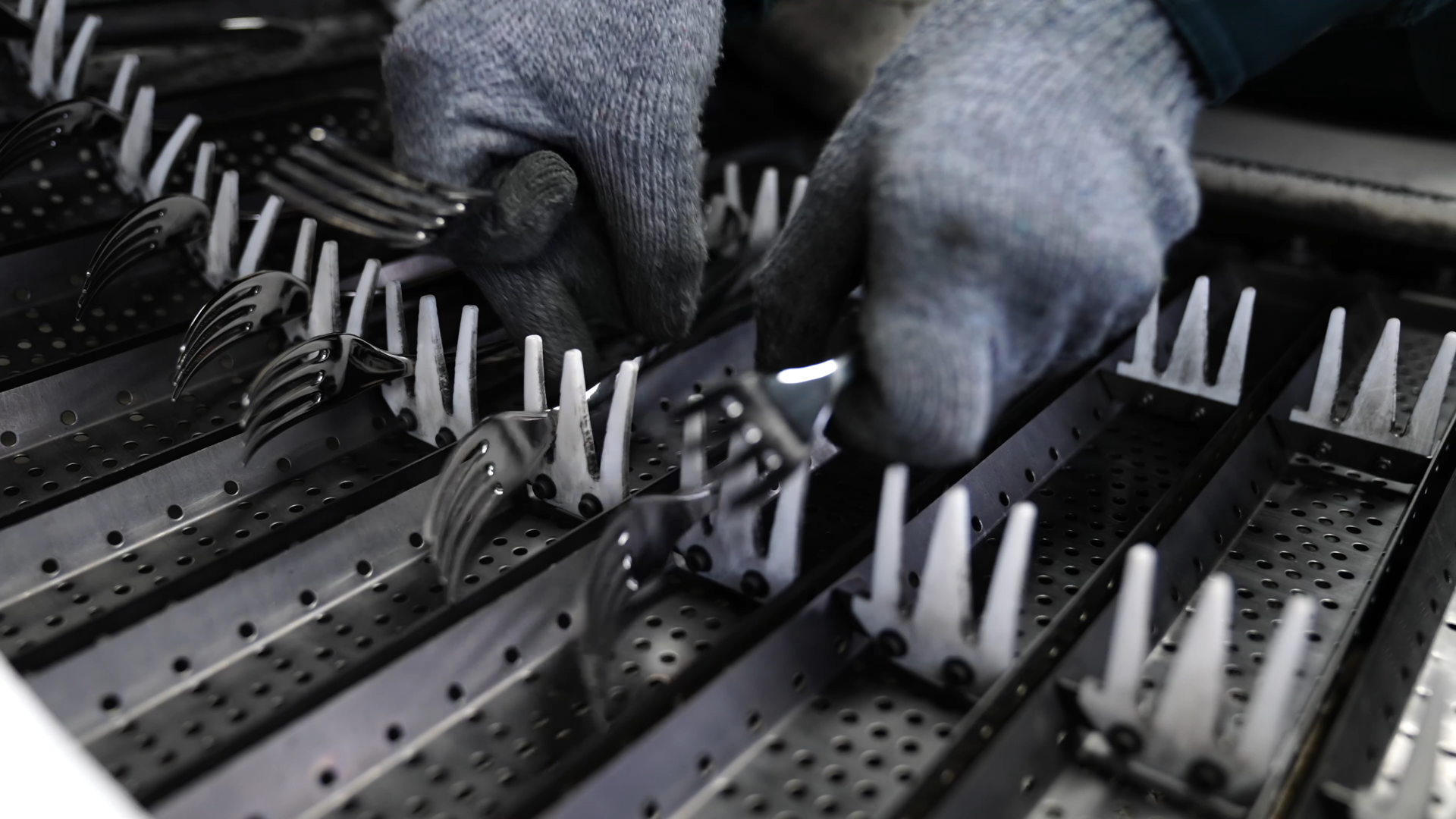

P9.Surface Polishing (Automatic Polishing)

Process P9、"Surface Polishing" (Automatic Polishing)

Ten to twenty spoons or forks are clamped together in a large clip and polished across a total of eight polishing machines. The six machines in the front handle the heads, while the two in the back handle the handles. Like a baton relay, each transfer gradually increases the shine of the cutlery.

Since shapes vary by product, subtle adjustments are needed to match the depth of the head and the curve of the handle. To prevent unpolished spots, the craftsmen check the finish as they work, adjusting pressure as they go.At times, the strong pressing reflects the experience and intuition that guides their hands.

On to the next stage. the Washing & Inspection Factory 【Area C】

▶S9.The Final Process That Turns It into a Lifelong Piece

After going through forming and polishing, the cutlery is beautifully refined.

You have now reached the final area.

Here, the last finishing touches are applied to ensure that customers can use the cutlery with complete confidence. Whether mass-produced items or high-end pieces costing tens of thousands of yen each, every item is carefully washed and inspected individually, without compromise. Take a look at the surrounding shelves—they hold only products that have passed strict quality standards.

And then there is Tsubame Bussan’s flagship *Laurel* series. To meet the needs of dining cultures around the world, it offers a wide range of sizes and shapes, totaling 42 varieties. Each piece is used daily on tables at home and in restaurants, reaching people across the globe.

P10.Washing

Process P10、"Washing"

Although the cutlery shines beautifully after polishing, a thin layer of polishing compound and tiny metal particles still remain on the surface. The pieces are thoroughly cleaned for about 15 minutes using ultrasonic waves and solvents. Our company has introduced washing machines specifically for cutlery. Each piece is carefully placed on the conveyor to prevent scratches.

If the timing is right, you can see cutlery coming from the mechanical polishing area in the back left, transported on the conveyor belt, shining brilliantly. Follow the machines toward the back to see the freshly washed cutlery emerging from the washers. The finish is so mirror-like that you can see your own reflection. The washing is done at approximately 75°C, so please be careful—freshly washed cutlery is very hot and should not be touched.

P11. Inspection

Process P11、"Inspection"

Our cutlery comes into direct contact with your hands and mouth. That is why every single piece, even mass-produced items, undergoes individual inspection. Craftsmen first examine each piece visually, then carefully feel it with their hands to detect any abnormalities. They can even spot holes as tiny as 0.02 mm—finer than a human hair. This meticulous attention ensures the quality of our products.

If a defect is found, it is quickly marked with a red pen and returned to hand polishing, machine polishing, or washing. The process is repeated as many times as necessary until the piece passes.

What is upheld here is safety and trust—the final, essential check to ensure that our cutlery brings peace of mind to your table.

P12.Packaging

Process P12、"Packaging"

Approved products are carefully packaged to prevent scratches from vibrations during transport, completing them as finished goods. For the commercial market, they are typically packed in boxes of one dozen (12 pieces). What you see being placed into boxes before you is exactly how they will arrive in your hands.

Finally Complete. Ready for Shipment!【Area D】

P13."Shipping"

Process P13、"Shipping"

Once packaged, the spoons and forks are finally ready for shipment as finished products. Packed in boxes, they embark on a journey to tables across Japan and around the world. Tsubame Bussan cutlery is used in top hotels in Japan, luxury hotels overseas, as well as in famous theme parks, family restaurants, and fast-food chains.

For over 110 years, our products have reached countless dining tables. We take pride in knowing that Tsubame Bussan cutlery is likely present in homes like yours as well.

▶S10.What Our Cutlery Is

The cutlery we create is meant to accompany you at your dining table throughout your life. While chopsticks are central to Japanese culture, a spoon is used for a baby’s first meal. As you grow and your life stages change, there may come a time to replace your cutlery, but it is truly a lifelong item. When that time comes, we hope you think of Tsubame Bussan cutlery—it would make us very happy.

We will continue to support the moments of “itadakimasu,” enriching your life through the joy of dining.

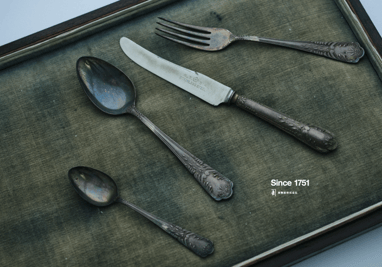

P14.Finished Product

Process P14、"Finished Product"

A warmth and shine that make it hard to believe these pieces were born from cold, hard stainless steel. Right before you, the finished products are displayed. Please pick them up and touch them—scoop, roll, or handle them. Simply performing everyday motions will allow you to feel their ease of use and smoothness. You will also experience the craftsmanship embedded in the details with your own hands.

This is the very essence of Tsubame Bussan’s world-class craftsmanship.

Thank you for your time! This concludes the Tsubame Bussan Factory Tour.

We sincerely appreciate you listening until the very end.

Tsubame City, one of Japan’s leading manufacturing towns, has a long history of metal cutlery craftsmanship that continues to thrive today, carried forward with the pride of our artisans. From seasoned craftsmen to the younger generation, skills are passed down daily across generations. As you’ve seen, each piece of cutlery embodies the techniques and passion of craftsmen dating back to our founding, as well as the teamwork of the entire factory. We invite you to handle the products yourself to feel their shine, weight, and the reliable quality that ensures they can be used for a lifetime.

Tsubame Bussan cutlery is a lifelong tool to be treasured. We hope it will accompany your everyday life for years to come, enriching your dining experiences.

Finally, a word about our new initiative: the tentative *“Universal Factory”* project. I am Sasage, Executive Director, who produced this audio guide.

Did you enjoy it?

Our goal was to find a way for anyone to enjoy an immersive experience of everyday craftsmanship—without diluting it, allowing visitors to seamlessly experience the extraordinary. There is still much we want to share, including stories about our history and products, and interviews with veteran craftsmen. We hope this content will continue to grow so that every visit offers new discoveries. Please look forward to what Tsubame Bussan will bring in the future!

We look forward to seeing you again next year.

Thank you very much for visiting Tsubame Bussan today!

2013 Copyright(C) tsubame bussan All rights reserved